Sorry... This site requires a JavaScript enabled browser.

Replacing cultivator legs, wings and points can be a depressingly regular and ruinously expensive pastime for those working in the nation’s most abrasive soils. Tungsten Carbide Guide Roller

But instead of hunting around for the cheapest metal, it can often make more sense to opt for higher-end options which, although pricier, can last several times as long.

Added to that, the sleek designs of some of these parts means they do a better job, are kinder to the soil and take less power to pull.

See also: Why Lincs contractor Rockscape relies on subsoiling toolbar

The secret to this is the inclusion of ultra-hard materials, such as tungsten carbide, at the main wear points, which allow manufacturers to give parts longevity without having to make them bulkier.

Another bonus of this approach is that parts are more likely to maintain their shape as they wear, meaning they should do a more consistent job throughout their lifespan.

The only downside, other than cost, comes for those on particularly stony ground, where the hard material can get chipped or knocked off.

Replacement cultivator metal also gives the possibility of altering the performance of an existing machine.

For example, swapping deep subsoiler legs for shallower-working, low-disturbance assemblies that lift without damaging the structure and disturbing too much soil at the surface.

For those handy with a welder, another option is to graft harder-wearing materials onto existing parts to help extend their lifespan.

Traditionally, this has been done with hard-facing weld, but now strips of tungsten carbide tiles on steel backings are available for on-farm fitment, as well as weldable materials such as Ferobide and Maxlife.

Yorkshire firm JJ Metcalfe specialises in custom bolt-on, weld-on and full-leg assemblies that improve the performance of existing machines.

NGLT leg and strips © JJ Metcalfe

Best known of the products designed by director Mike Metcalfe and his team is the deep-working NG leg.

This has a modular design with a series of interchangeable wings, points and shins so that it can be tailored to suit different working depths and conditions.

These have a slender profile but are faced with tungsten carbide tiles – attached using a specialist brazing technique – meaning they last considerably longer than bulkier solid steel alternatives.

The NG is designed to work at subsoiling depths of 20-35cm (8-14in), and buyers can fine-tune the setup by altering the modular components, such as wings, shins and points.

These can also be replaced as they wear, meaning the body of the leg has a very long lifespan.

The move towards shifting less soil in recent years has prompted the firm to introduce a couple of lower-disturbance options, one of which is the NGLT.

Like its deeper-working relative, this has replaceable points, shins and wings to give it a longer lifespan, but it’s designed to work at shallower depths of 10-20cm (4-8in).

The key difference in its design is a shallower wing pitch that lifts soil without causing too much disturbance at the surface.

For even less movement, buyers can opt for the CS leg. This performs a similar function to the NGLT, but it has a sleeker profile meaning it cuts an even cleaner slot through the ground.

The only downside is that it doesn’t have replaceable wear sections, meaning it won’t last quite as long. Three versions are available with 10cm, 15cm or 20cm wings to suit different working widths and depths.

In most cases, JJ Metcalfe’s legs can be supplied as a full assembly to fit the original machine, a weld-on half leg, or a bolt-on bracket for 100mm box section.

Prices for the CS range start at £120 a leg, the NGLT is priced from £324 and the original NG starts at £385.

Other product offerings include steel-faced tungsten carbide strips, which can be welded onto existing machines, and direct-drill coulters that allow buyers to build their own cultivator or adapt an existing model.

The firm also designs and builds original equipment for big-name brands such as Kverneland and He-Va, in addition to smaller outfits including Plowman Brothers and TerraTech.

Agricast offers a broad range of conventional and tungsten carbide-tipped wearing-metal parts to suit a variety of cultivators and ploughs.

LDX 125mm tungsten wings © Agricast

Most of these are a similar shape to makers’ original parts, but some have been adapted to better suit customers’ needs.

Popular options include the LDX, which is based on the Simba LD point and is designed to work from 25-33cm (10-13in).

There’s also the GLX, which is similar to the Sumo GLS with a 13-20cm (5-8in) working range and the SLX that’s inspired by the He-Va Stealth.

Alternatively, Agricast offers a service to modify existing machines to run different legs, with the current trend moving towards lower disturbance. Examples include Cousins V-Forms, Simba Flatliners and McConnel Shakaerators.

LDX Point and 175mm wing after 120ha © Agricast

Prices for full-leg assemblies range from £120-£200, while five-tile tungsten points for an LDX cost £70 each and tungsten wings range from £55-£65 depending on width.

Tungsten tips and wings for the GLX and STX are priced at £85 and £78, respectively.

Buyers that want to avoid tungsten – such as those on very stony ground – can opt for cheaper versions without the tiles fitted.

The Maxipart range of wearing metal from Hampshire firm APM is constructed out of a durable steel alloy with both tungsten carbide tiles and hard-facing welds used to extend the lifespan further.

Most of the parts in the catalogue are similar in shape to cultivator makers’ original equipment, but APM says its engineers tweak the designs so they perform better and last longer.

Previous successes have included a custom slimmer point for the Sumo Trio, which is easier to pull than the original and moves less soil.

However, the trend toward lower disturbance cultivations has seen the focus shift to even more slender legs.

Now the firm’s own versions of Sumo’s LDS, He-Va’s Stealth and Grange’s toolbar leg have become its best sellers.

The two former legs are similar in design, featuring tungsten carbide on the leading edges and to the top of the shin, as well as hard-facing weld on the sides, which the firm says dramatically alters the lifespan.

Grange legs come in two versions, both of which incorporate tungsten and hard-facing in differing quantities depending on price and how aggressive the soils are.

The original point has tungsten on the nose and wings and halfway up the shin, with further hard-facing to the top.

On very aggressive soils, this hard-facing can wear back so another version is available with tungsten all the way up.

As this will wear longer on aggressive soils, further protection is added to the back of the point in the way of hard-facing, which will help to extend the life of the leg.

Bison Duratil parts sold by Agri-Linc use a base material of white cast iron alloyed with nickel and chromium, which the Lincolnshire firm claims lasts at least five times longer than standard metal.

Another benefit is the fact that it can be attached with regular mig or arc welding, but it is a little brittle so isn’t best suited to rocky conditions or being bashed down hard onto concrete.

Buyers can purchase complete replacement parts that can be clicked, bolted or welded in place, or weld-on sections that can be used to reinforce or refurbish existing parts.

For added durability, the firm has a premium range of components that use the same base metal with tungsten carbide on the leading edges.

A popular all-in-one component is the Sumo 4in low-draft point, which features tungsten tip, Duratil wing edges and a triangular shin wear protector. These cost £147.50 each.

Canadian outfit Bourgault Tillage Tools is a huge name in the cultivation equipment world, but it’s still a relatively small entity in the UK.

However, since setting up its Peterborough-based UK subsidiary in 2021, the firm is slowly expanding its product offering, including a range of harder wearing metal parts.

These Maxlife components are layered with runs of specialist weld that contain solid chunks of tungsten carbide in the main wear areas.

According to the maker, this doesn’t chip or flake when subjected to hard impacts and it can increase the lifespan of parts by six to eight times.

Initially, the Maxlife treatment was only available as weld-on wear strips (see “DIY weld-on wearing metal”), but UK buyers now have access to a range of straw harrow tines. Prices for these range from £25-£45/tine

depending on the size. More cultivator wearing metal will be added to the lineup in the next few years, with the focus on upgrade parts that improve performance and longevity.

The firm also offers a low-disturbance Versatile Opener System for tine drills such as Horsch’s Sprinter and CO drills, as well as an upgrade for the Weaving Sabre Tine that has a replaceable tip.

For years, hard-facing weld was the main method of laying down wear-resistant material onto cultivator parts to extend their lifespan.

But, to add even more resilience, there’s now the option of weldable strips of ultra-hard compounds such as tungsten carbide.

Careful placement is key to getting the best from these products so that they don’t exacerbate wear in other areas or alter the performance of the part. Some retailers will offer guidance to help customers get this right.

Tungsten carbide is the champion of wearing materials, with an ultra-hard chemical composition that helps it withstand being pulled through abrasive soils.

The only problem is that this metal-ceramic composite can’t be welded, meaning the only method of attaching it to steel is via a specialist brazing technique, which generally needs to be done in a factory environment.

On-farm fitment is possible though, by purchasing strips of tungsten carbide tiles brazed onto steel backing plates that can be welded in place.

These make the strips easy to fit, but the extra metal adds bulk and welds need to be strong and well-positioned to resist excessive wear. The strips are available from most suppliers that sell wearing parts fitted with tungsten carbide.

Another consideration is that the material is a little brittle, meaning it can get chipped in particularly stony soils. There are slightly softer compositions available for this purpose.

To combat some of tungsten carbide’s limitations, Manchester firm Tenmat developed a product called Ferobide.

Like its forbear, Ferobide is made from both metal and ceramics but, crucially, it uses a steel matrix to bond the tungsten particles together, allowing it to be mig- or arc-welded directly onto cultivator metal.

Stewart Peckitt of Peckitts Ferobide is the distributor of the product into the agricultural sector and says the material can dramatically extend the lifespan of wearing parts, even those fitted with tungsten carbide at the leading edges.

In this instance, the tiles are installed in the “wash” area, which can wear away well before the tungsten carbide at the leading edge.

Trials have been carried out on several farms, one of the most dramatic of which was using Simba Prolift legs on abrasive soil.

Here, plain steel wings were apparently showing excessive wear after just 38ha, while examples edged with tungsten carbide managed 240ha and those featuring both tungsten carbide and Ferobide apparently lasted for 1,000ha.

Correct installation is important to get the best from the tiles and the firm issues buyers with a set of guidelines to help position and attach them correctly.

As for the longevity of welds, Stewart says they do wear a little over time, but the action of soil flowing over the Ferobide protects them from severe damage.

Another alternative is Borgault’s weldable Maxlife strips, which are coated with the same compound used on the firm’s harrow tines.

Like tungsten carbide strips, these have a weldable metal base plate that has the Maxlife weld treatment applied to the surface.

As per the tines, this claims to extend the life of parts by six to eight times.

Buyers can weld the strips in place using a mig or arc welder and they’re available in 12mm, 15mm or 25mm widths, all of which come in 30cm lengths. Prices are £14, £15 and £25, respectively.

Agri-Linc’s Bison Duratil material is available in individual sections that can be welded in place to strengthen or refurbish existing components.

Examples include 30cm leading edges, which cost £29.50, triangle shin protectors priced at £27.50 each, £19.70 points and Hardox weld-on side wear plates that start at £15.30.

Using contractors saves you time and money. Now you can book, track and pay all in one place. Register for early access today.

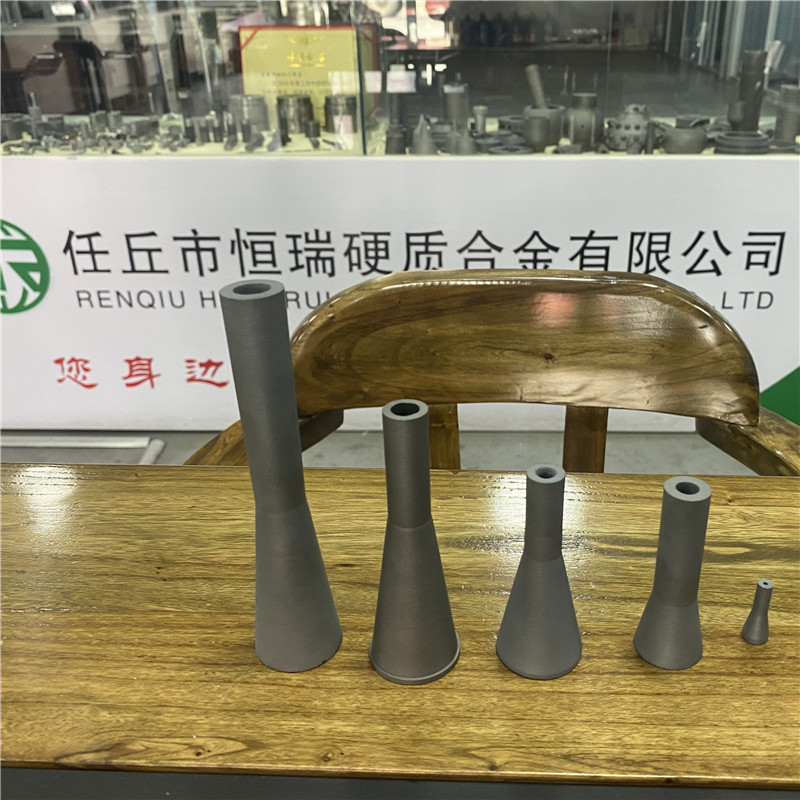

YG15 K034 Tungsten Carbide Visit our Know How centre for practical farming advice